FEATURES

-

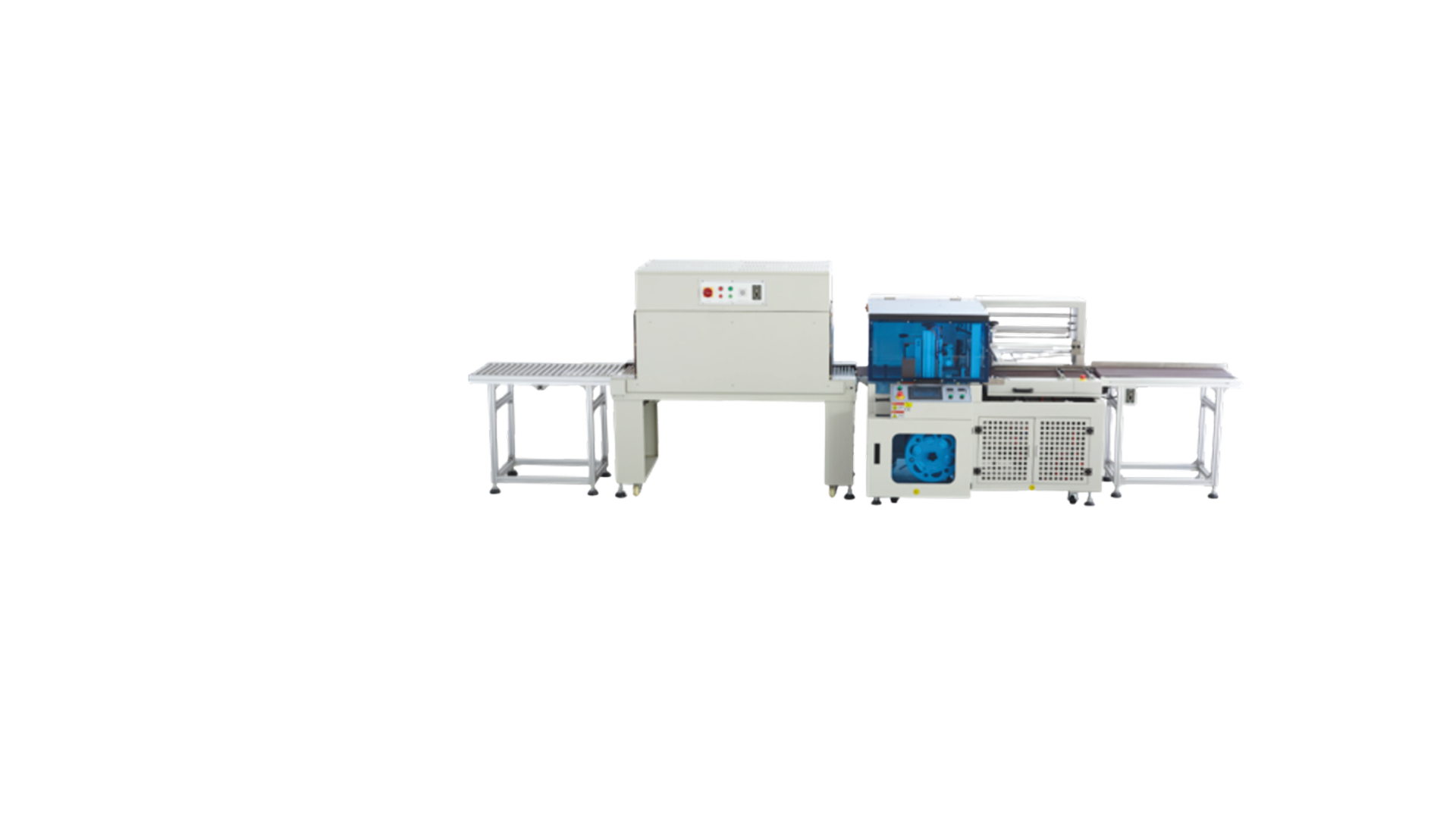

Automatic film unwinding with motor-driven rollers and tension control mechanisms.

-

Conveyor belt for automatic product feeding in a straight direction.

-

Easy transfer to the tunnel with automatic discharge conveyor.

-

Optical sensor control for package feeding.

-

Hot jaw system that both seals and welds with a jaw blade.

-

Patented design jaw system for long-lasting cutting and sealing.

-

Cutting jaw with digital thermostat with +/- 1 degree temperature control.

-

High-quality welding with special long-lasting profile silicone in the lower jaw.

-

PLC programmed control mechanism and flexible program opportunity.

-

Rational energy control and insulation with special design in the heat tunnel.

-

Different options for soft and easy product transfer from the belt surface.

-

Approach sensors on the jaw for finger and package safety.

-

Ability to feed mixed-size products in succession with the automatic product size measuring system.

-

Excess nylon waste on the right and left sides is automatically cut.

-

Cut waste is automatically discharged.

-

The waste compartment is automatically discharged with compressed air.

-

ISO 9001 and CE

-

5 Year Spare Part Supply Warranty

OPTIONS

-

Sensor-controlled safety special protection covers.

-

Package top printing system.

-

Heat-resistant Teflon mesh belt to prevent nylon adhesion on the tunnel conveyor.

-

The machine can be produced with A430 - A304 - A316 grade stainless steel chassis.

-

Special metal or wooden case application can be made for transportation.

-

Can be designed without an oven

WITH THIS MACHINE

-

Medium-sized and large businesses can easily meet their packaging capacities.

-

You will ensure minimum nylon consumption with equal amount of waste control.

-

You can wrap your products of different sizes with cargo bags.

| Model | Dimensions E*b*y | Jaw Size | Max Film Width | Full Power (KW) | Average Power (kWh) | Production Capacity | Weight |

|---|---|---|---|---|---|---|---|

| PE- 50x70 | 1200mmx6100mmx 2200mm | 700 mm | 650 mm | 31 KW | 18 kWh | 12-15 Pk/Dk | 750 Kg |

| PE- 50x150 | 1200mmx9000mmx 2200mm | 1500 mm | 1450 mm | 60 KW | 33 kWh | 6-10 Pk/Dk | 1750 Kg |

Other Machines