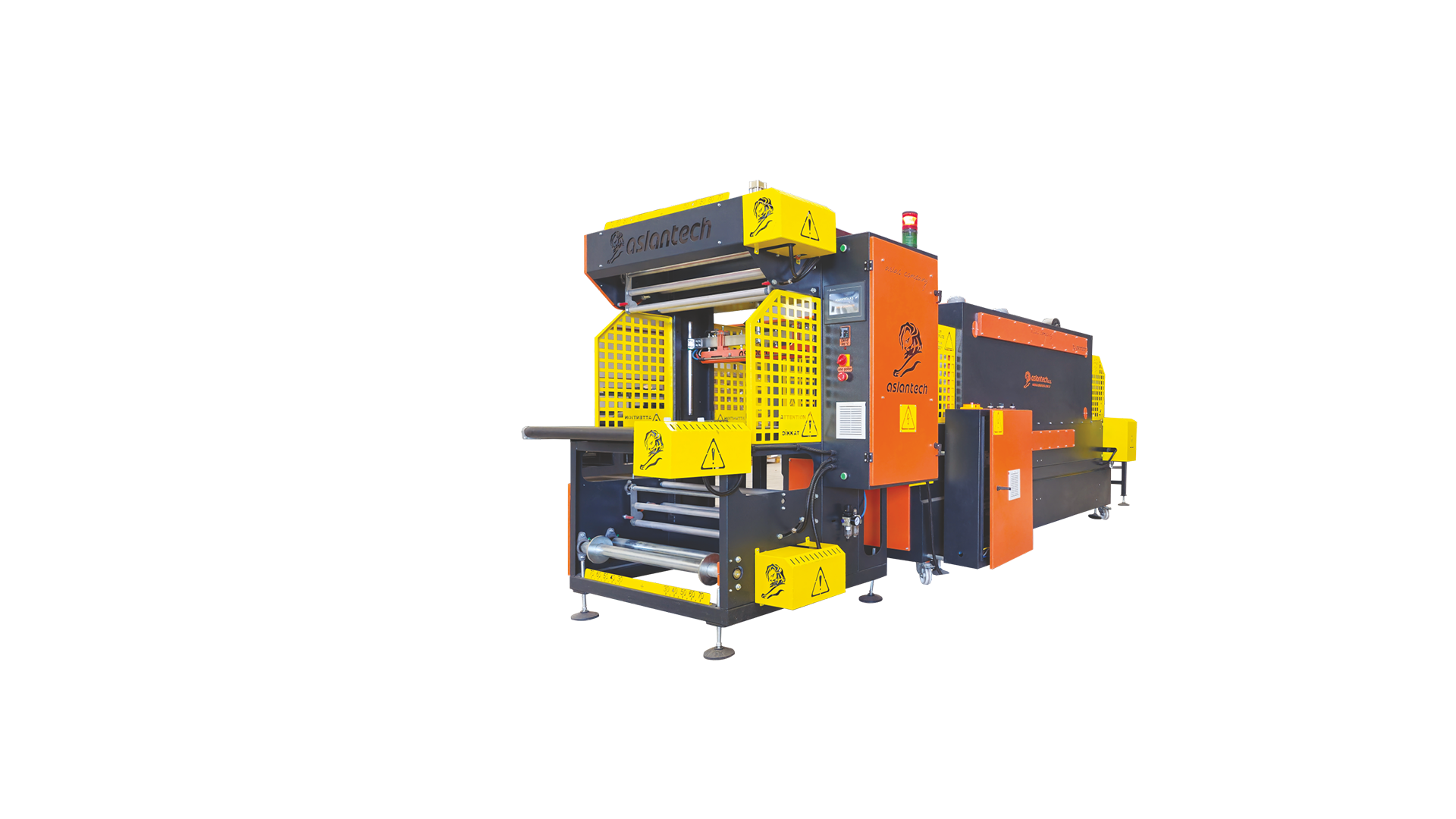

FEATURES

-

Energy saving and excellent package quality with fan technology that provides homogeneous heat distribution

-

360-degree high-quality shrinking process opportunity, suitable for the principle of (Cut First) then shrink.

-

Linear motion feeding table and film carrying car.

-

Control panel where all times and temperatures can be adjusted

-

Hole drilling apparatus for air discharge

-

ISO 9001 and CE

-

5 Year Spare Parts Supply Warranty

OPTIONS

-

Optional automatic cover system that does not tire the operator with the addition of a pneumatic system

-

With the optional electromagnet option in the spring-loaded cover mechanism, the cover automatically opens at the end of the process.

-

The entire machine can be manufactured with A430 - A304 - A316 grade stainless steel chassis.

WITH THIS MACHINE

-

You Save Space

-

You Save Energy

-

You Can Pack Practically

-

You Do Not Need Industrial Electricity (3 phase)

| Model | Dimensions E*b*y | Jaw Size | Max Film Width | Full Power (KW) | Average Power (kWh) | Production Capacity | Weight |

|---|---|---|---|---|---|---|---|

| POF - PVC 45x60 | 1600mmx900mmx 1050mm | 450mmx600mmx120mm | 550mm | 3.6 KW | 2 kWh | 6-10 Pk/Dk | 120 Kg |

| POF - PVC 50x70 | 1650mmx950mmx 1200mm | 500mmx700mmx120mm | 650mm | 4.6 KW | 3 kWh | 6-10 Pk/Dk | 135 Kg |

| POF - PVC 60x80 | 2000mmx1100mmx 1200mm | 600mmx800mmx120mm | 950mm | 6.8 KW | 4 kWh | 6-10 Pk/Dk | 210 Kg |

| POF - PVC 75x105 | 2600mmx1700mmx 1200mm | 750mmx1000mmx120mm | 1000mm | 8.6 KW | 6 kWh | 6-10 Pk/Dk | 450 Kg |

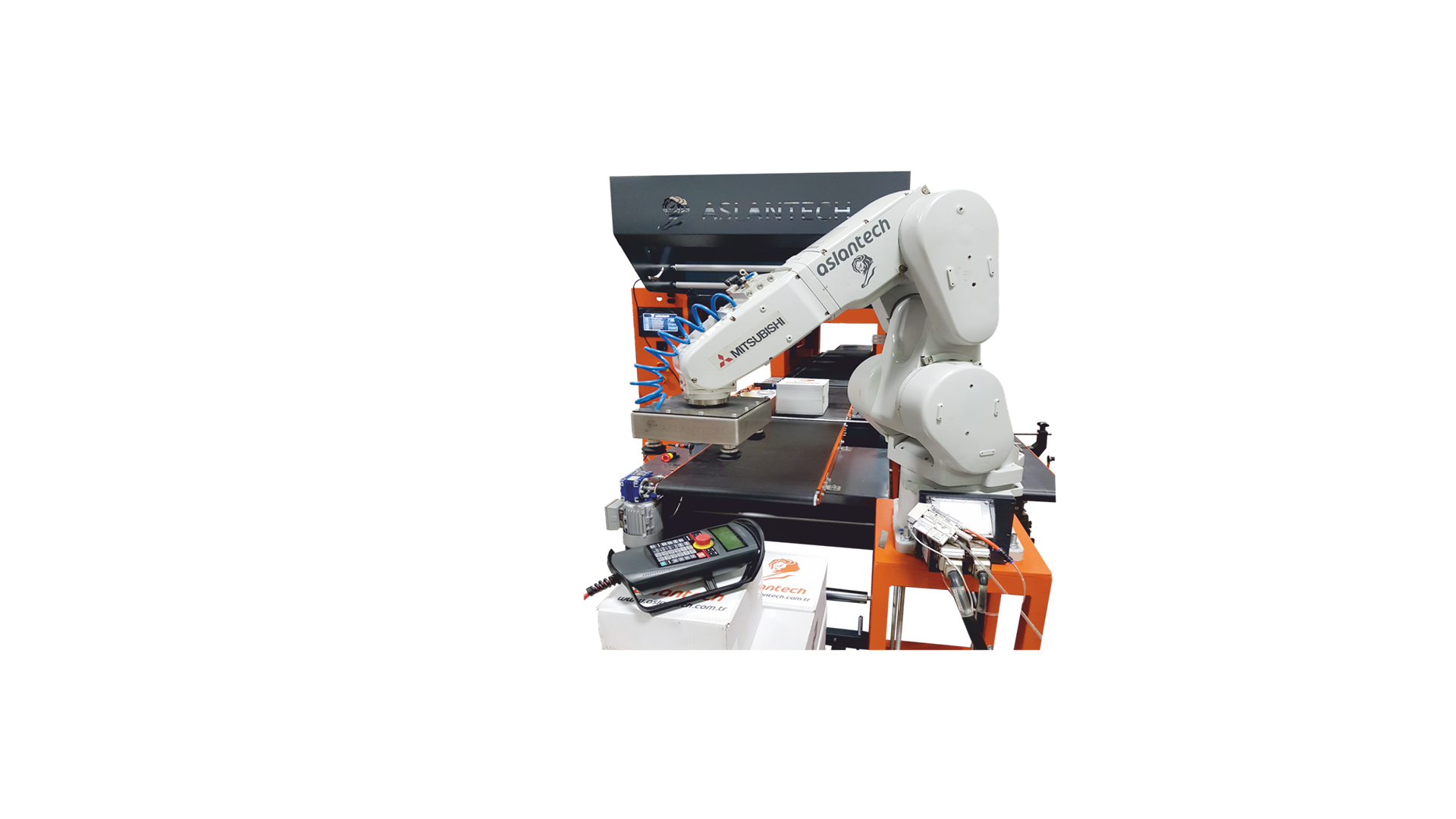

Other Machines